In short Test results from the Biomechatronics Laboratory of FH Münster - University of Applied Sciences confirm: The innovative SecuTec Genu Flex stabilizes the knee joint reliably according to the 4-point principle. The semi-flexible brace has the same mechanical stabilization effects as the tried-and-tested SecuTec Genu hard-frame brace – with the difference that its mobile Flex-Links can adapt to the thigh and lower leg during movement. Prof. Dr.-Ing. David Hochmann and Maxim Kirillov conducted the model-based test procedure and talk about challenges, insights and forecasts.

Orthosis·Knee pain

SecuTec Genu Flex assessed in a stabilization test

The same security as provided by a hard frame

From Bauerfeind Life on 06.08.2025

Does the semi-flexible SecuTec Genu Flex frame brace stabilize like its classic equivalent, the SecuTec Genu hard-frame brace? Prof. Dr.-Ing. David Hochmann, Scientific Director of FH Münster’s Biomechatronics Laboratory investigated this question. He has developed a laboratory test procedure for knee braces and obtained his doctorate in 2010 for his dissertation “Test and Assessment Methods for Knee Braces”. Bauerfeind life spoke to him and his doctoral candidate Maxim Kirillov M. Sc. about benchmarks, working to create standards for test procedures, and the future of technical orthopedics.

What did you find out when comparing the innovative SecuTec Genu Flex and the dorsal version of the SecuTec Genu hard-frame brace?

Prof. Hochmann: With respect to its mechanical stabilization properties, the SecuTec Genu Flex is similar to the SecuTec Genu, both on a sagittal and horizontal plane. The fact that its mobile Flex-Links adapt to the thigh and lower leg when the knee moves is not a detriment to the efficiency of the orthopedic 4-point principle.

Which procedure did you use to test the SecuTec Genu Flex?

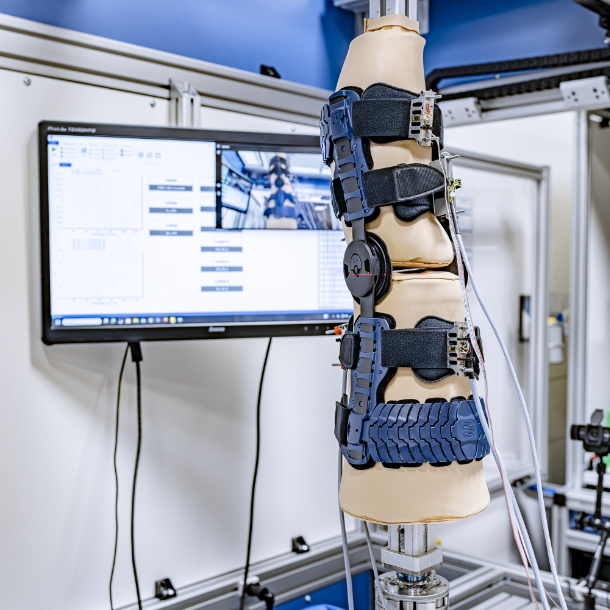

Prof. Hochmann: In order to portray use during treatment in a simplified, yet realistic way, loads that can easily cause injuries test where the brace should be stabilizing the knee joint and the ligaments. In order to do this, single-axis movements defined as relevant, i.e. anterior-posterior translation and internal as well as external rotation, are generated in a test rig using a leg model that follows the human anatomy, an anthropomorphic phantom. The brace exerts a stabilizing effect during this process, which can be assessed using the resulting force-path or torque-angle characteristic curves. The thigh and lower leg in the leg model are not separated by a reproduction of a knee joint, instead there is a gap between them. It’s only the brace that makes the connection, meaning the load is transferred directly.

Why did you need a comparative situation?

Prof. Hochmann: One of the major challenges is the lack of normative specifications for medical aids, such as braces for the knee or lower leg. That’s why VDI Guideline 5703 “Systematic Development of Model-based Tests for Medical Devices” was used as a foundation for developing the test procedure in order to guarantee reproducible statements and a robustness when it comes to potential external influences. Without a binding test standard, we don’t have any absolute assessment parameters that can be used without limitations. For this reason, the stabilization effects of the SecuTec Genu Flex are assessed in a comparison with a tried-and-tested product, such as the SecuTec Genu hard-frame brace.

In order to establish procedures that will be binding in the future, a team of us from FH Münster has joined the standardization group called “Laboratory Test Procedures relating to Braces for the Lower Extremities” organized by the German Institute for Standardization (DIN). Together with Bauerfeind and some other companies as well as institutes, we’re developing a first standard.

”With respect to its mechanical stabilization properties, the SecuTec Genu Flex is similar to the SecuTec Genu, both on a sagittal and horizontal plane.“

Prof. Dr.-Ing. David Hochmann

What challenges did you face during the test process?

Maxim Kirillov: This mainly included guaranteeing a comparable donning situation on the leg phantom. Sometimes, this required a lot of effort because the forces exerted by the straps are constantly monitored with specifically developed sensors. The SecuTec Genu Flex was very easy to don on the phantom, and overall easier than the SecuTec Genu, but attaching six strap sensors was quite a challenge. The order was important, too. We therefore also measured the donning procedure and recorded it on video.

In order for a laboratory test procedure to maintain its connection to clinical reality, the interaction between patient and medical aid also has to be modeled in the design. Another challenge therefore was the migration, the axis incongruence between the brace and the knee test rig, which was exacerbated by the conical shape of the leg. This led to a greater variability in the test results and interfered with the separation precision of the assessment in the end. That’s why we set up the leg phantom upside-down, i.e. with the lower leg at the top.

How do you judge the innovation of the SecuTec Genu Flex, meaning the adaptability of the frame to the thigh and lower leg?

Prof. Hochmann: One of the major limitations of treatment effectiveness when it comes to knee braces is patient acceptance. All design aspects that aim at meeting patients’ requests for increased freedom of movement must generally be welcomed – especially if they don’t result in a deterioration of stabilization properties, and the same mechanical security remains. Whether these attempts will actually lead to an increase in compliance and therefore better treatment success will have to be tested in future clinical examinations.

What progress in care has (knee) orthotics made in the last ten years, and which opportunities for the future does technical orthopedics have?

Prof. Hochmann: Key developments in technical orthopedics relate to the increased use of additive manufacturing processes. These are actually perfect for medical technology with low unit numbers. This makes customization cost-effective. I can imagine that, in the foreseeable future, there will be no more “over-the-counter” braces, and that industrially made knee braces will be more customizable, which will result in improved effectiveness and a higher level of wearing comfort.

Service information

You can request an overview of the results from the laboratory test regarding mechanical stabilization from medical.affairs@bauerfeind.com.

The SecuTec Genu Flex used in knee treatment

The SecuTec Genu Flex stabilizes the knee joint according to the 4-point principle. Its lightweight plastic frame consists of unique mobile Flex-Links that adapt to the thigh and lower leg. Find out more.

Pictures: Sven Hillert, Bauerfeind AG

Related topics

Product-Finder App

This app greatly simplifies the selection of suitable medical aids for doctors and specialist dealers. With its intuitive usability, information on Bauerfeind products is available everywhere – quickly and easily